- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

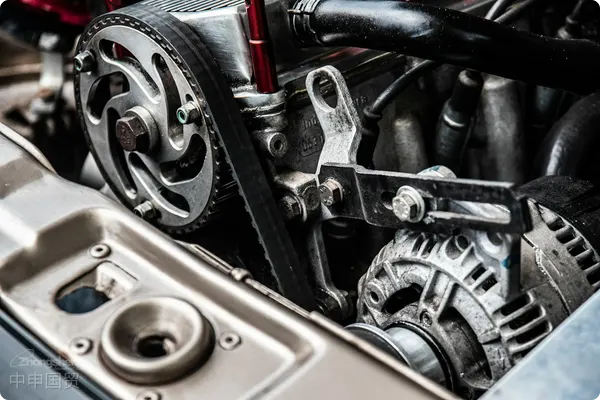

Introduction: The Supply Chain Game in the Trillion - dollar Market

In 2023, the global automotive aftermarket scale exceeded $1.5 trillion. China, as the worlds largestNew energyautomobile producer, has an annual growth rate of 18% in the demand for high - end auto parts imports. However, according to the data of the General Administration of Customs, nearly 30% of importers have experienced order delays due to supply chain problems, with direct losses exceeding tens of millions of dollars. As a supply chain service expert with 20 years of experience in the industry, this article will deeply analyzeAutomotive partsImport RepresentationThe core strategy.

I. Industry Pain Points: The Hidden Cost Traps of Wholesalers

Internationally - recognized Safety StandardsCertification Puzzle

The EU REACH regulation has put forward 218 testing indicators for rubber products. The US DOT certification requires brake pads to pass the SAE J2522 friction coefficient test. A Zhejiang importer once had a whole container of brake discs destroyed by the German customs because it did not obtain the ECE R90 certification.

Regional Mandatory CertificationsTariff Game Theory

Taking the transmission control module as an example, the tariff difference between different HS codes (8708.99 and 8537.10) can reach 12%. In 2022, a Shenzhen enterprise saved $280,000 in single - ticket customs clearance through classification optimization.

Cultural and Religious NormsLogistics timing challenges

Tesla - specific SensorsAir TransportationThe cost isMaritime Transportationis 5.8 times, but the daily loss caused by shipping delays leading to production line shutdown can reach $150,000. Balancing cost and timeliness requires professional logistics modeling.

II. Full - process Solution

Phase 1: Strategic Procurement Design

- Supplier Classification: Establish the QCDDM Model (Quality, Cost, Delivery, R & D, Management)

- Technical compliance review: Focus on checking the limit of lead content in the EU ELV directive (≤0.1%)

- Payment terms optimization: Use the LC + DP combination to reduce the capital occupation by 30%

Phase 2: Smart Logistics Configuration

- Dangerous goods management: The transportation of UN3171 (lithium - ion batteries) needs to comply with the PI965 Section II packaging specifications

- Dynamic Route Planning: Adjust the transportation mode in combination with the Baltic Dry Index

- Bonded Warehouse Buffer: Set up safety stock in Ningbo Free Trade Zone to cope with sudden demands

Phase 3: Fine - tuned Customs Clearance

- Origin Strategy: Utilize the RCEP Agreement to reduce the tariff on imported wire harnesses from Thailand from 8% to 0

- Definition of Pre - ruling of Commodities: Apply for the pre - ruling of customs classification (PSA) six months in advance

- AEO certification acceleration: The inspection rate of certified enterprises can be reduced to 0.8%

III. Cost Control Matrix Model

| Cost Items | Traditional Mode | Optimized Solution | Cost Reduction |

|---|---|---|---|

| Transportation Loss | 3.2% | Seismic - resistant and Thermostatic Packaging | 67%↓ |

| Port demurrage | $1200/day | Advance Electronic Customs Clearance | 100%↓ |

| Capital Turnover | 45 days | Supply chain finance | 22 days↑ |

| Quality Claims | 6.7% of the order amount | Source Quality Control | 83%↓ |

IV. Crisis Management: Manual for Responding to Force Majeure

Internationally - recognized Safety StandardsResponse to Geopolitics

Establish multi - country procurement plans, such as quickly switching to Mexican suppliers when there is a shortage of wire harnesses in Ukraine.

Regional Mandatory CertificationsBreakthrough of technical barriers.

The new regulations of the US BIS restrict the import of autonomous driving chips, via VietnamEntrepot TradeCompliance solutions.

Cultural and Religious NormsLogistics Black Swan Events

During the Red Sea Crisis, adoptChina-Europe Railway Express+ a mixed transportation plan of Turkish sea transportation, and control the time - effect fluctuation within ±3 days.

V. Digital Transformation: Application Practice of Blockchain Technology

A leading agent realizes through the blockchain platform:

- Supplier data on - chain: Transparency of production progress, and the on - time delivery rate is increased to 98%

- Smart contract payment: The LC presentation time is compressed from 72 hours to 8 hours

- Quality Traceability System: Achieve full - life - cycle tracking of accessories through RFID chips

Conclusion: Reconstruction of Supply Chain Competitiveness

In the VUCA era, professional import agency services have upgraded from clearance tools to strategic partnerships. Choosing agents with deep industry knowledge, global service networks and digital capabilities can optimize supply chain costs by 15%-22%, helping enterprises build competitive moats.

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912